Intralogistics within the food & beverage industry demands a high level of sensitivity. Our automation solutions are designed to intelligently handle the growing volume of smaller orders while ensuring FDA compliance and convenience for retail environments, accommodating a diverse range of products. We aim to optimize your warehouse operations to their fullest potential.

The proper and careful handling, storage and distribution of products is crucial for quality, freshness and safety in the food and beverage industry: even a minor error in the production, handling of raw materials, packaging or finished goods can have significant consequences for consumers. The demands placed on manufacturers by international regulatory authorities are correspondingly high.

Simultaneously, the food and beverage landscape is evolving with eCommerce-like dynamics. Markets constantly seek new products, driving faster product life cycles. Distribution channels now accommodate more frequent, smaller orders, and face unpredictable seasonal shifts. Thus, ensuring the availability of top-quality fresh goods under favorable conditions is crucial for meeting consumer demands.

To effectively meet the rigorous standards set by regulatory bodies like the FDA and KOSHA, and to satisfy increasingly demanding consumers in a competitive market, you're likely already in the process of automating material and goods handling, along with the necessary track and trace documentation.

With Stoecklin, you have a trusted partner offering proven expertise in fully automated intralogistics solutions. We can help elevate your internal storage and conveyance processes to a new standard. Our team of industry specialists will tailor a system precisely to your needs, incorporating modules manufactured to INOX quality standards, particularly suitable for temperature-controlled hygiene, wet, and deep-freeze environments.

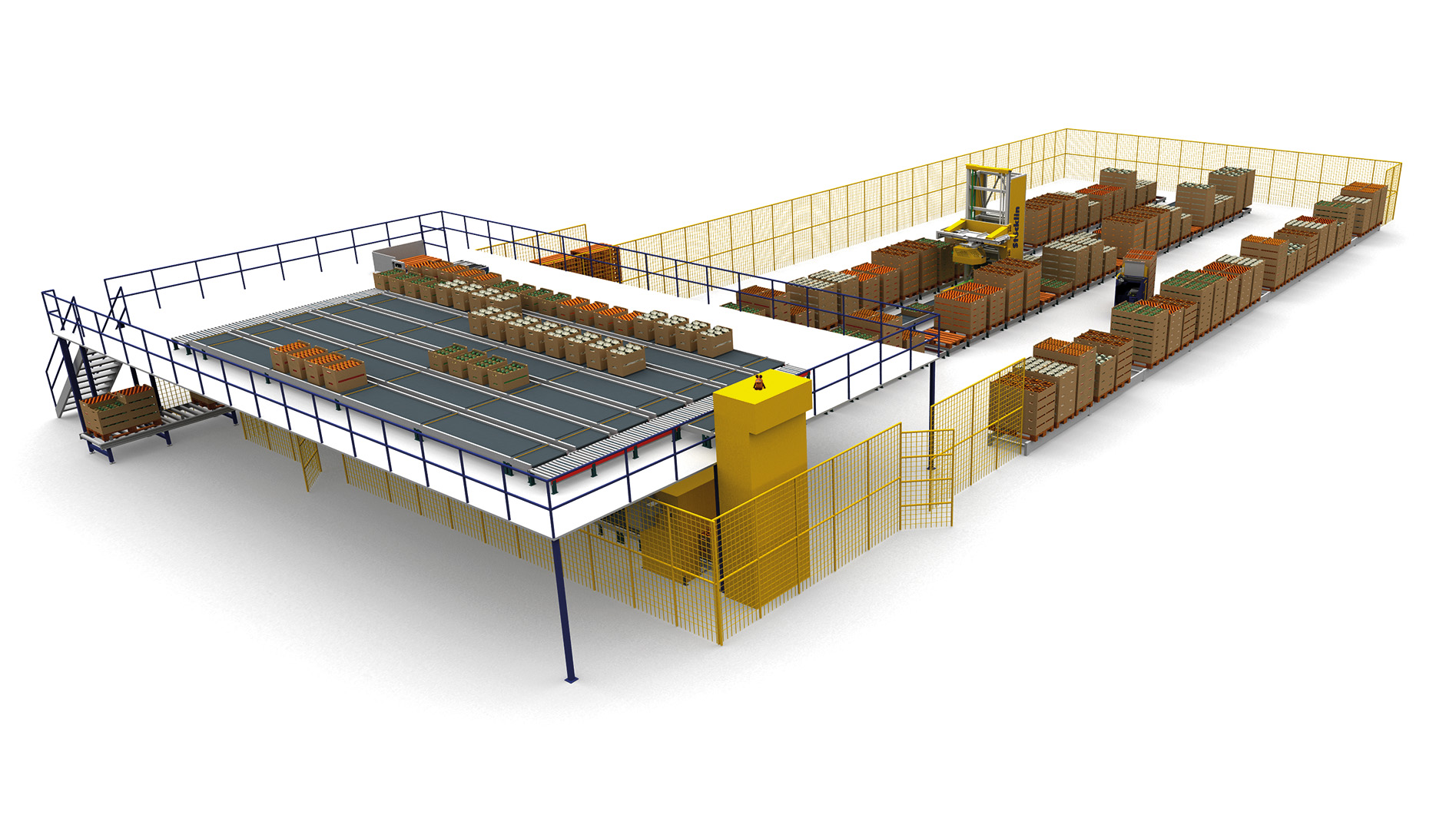

With our modular (high) racking systems, smart operating devices, conveyor systems and automated guided vehicles (AGVs) for your automated pallet warehouse, you get high-throughput, low-consumption and sustainable systems that you can easily adapt and expand in the future.

Innovative solutions like the Stoecklin CasePicker Solution enable fully automated pallet picking tailored to store requirements, ensuring optimal packing density on loading equipment. This includes cross-docking, directly transferring pallets without buffering or interim storage, enhancing order processing speed and reducing delivery times. The CasePicker prioritizes fast-moving items, efficiently handling sensitive food items even in damp packaging alongside heavier drink containers. It facilitates the creation of intelligently assembled, securely packaged, and store-friendly mixed pallets while minimizing labor requirements and physical exertion.

Furthermore, for end customer orders, we offer a comprehensive range of tried-and-tested forklifts, picking and pallet trucks, along with pick-by-light/voice technologies suitable for various operational environments. These solutions ensure seamless, error-free omni-channel fulfillment for the food and beverage industry.

Complete visibility and seamless goods flow are ensured through the intelligent logOS software suite developed by Stoecklin. This sophisticated system integrates warehouse management, material flow control, and data management, providing comprehensive monitoring and control over your system, inventory, product movements, and storage locations. With logOS software, you can efficiently track shelf lives in a fully auditable manner, automate replenishments, and implement optimized first-in-first-out protocols for each storage area.

By leveraging this software, you can streamline throughput times, optimize inventory levels, and reduce storage costs while maintaining full compliance with FDA/OSHA regulations. The system offers complete transparency of operational data, including batch or serial numbers, ensuring regulatory compliance and operational efficiency at all times.

In all aspects, we prioritize green logistics, employing intelligent energy management strategies and solutions that can lower electricity usage in your warehouse by as much as 20%. Our initiatives range from utilizing patented lithium-ion batteries and implementing fast-charging techniques to adopting low-wear, low-consumption approaches. We also focus on energy recovery, including the capture of braking energy, and implement intelligent route planning, which includes double-change calculations for our MASTer and BOXer storage and retrieval machines.

Bell Food Group AG, Basel, CH

A real alternative to the previously laborious manual order picking...

To Case Study

Emmi Schweiz AG, Ostermundingen, CH

Reorganization of intralogistics at Emmi Schweiz AG's Ostermundigen site: functional expansion, automation of goods transport using an automated guided vehicle system (AGV) and needs-based modification of the warehouse management system for greater process flexibility and handling.

To Case Study

Migros Cooperative Neuchâtel-Fribourg, Marin, CH

With predictive maintenance, sustainable drive technology and the lifecycle-oriented replacement of a total of 165 forklifts, a significant improvement in the operational readiness and cost-effectiveness of the forklift fleet was achieved - all thanks to a well thought-out concept.

To Case Study

Conservas La Costeña, Mexico City, MEX

As general contractor, Stöcklin planned and implemented the new warehouse and distribution center of Conservas La Costeña in Mexico City. The very high degree of automation of the installed Stöcklin intralogistics system increases the throughput capacity of the center to 260 pallets per hour.

To Case Study

Pfitscher butcher's shop, Burgstall, IT

The combination of two storage types ensures optimum use of space...

To Case Study