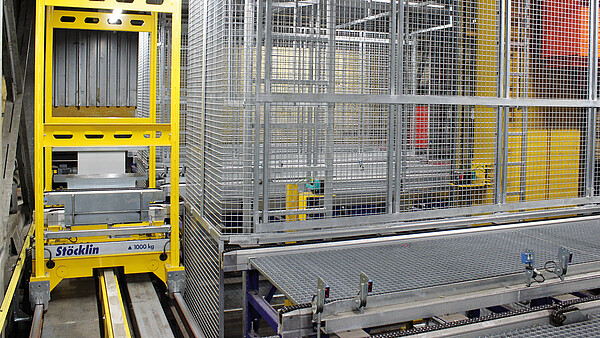

When it comes to retrofitting and upgrading, our decades of experience as a manufacturer and supplier of complete intralogistics solutions make the modernization professionals at Stoecklin the partners that can turn your old systems into solutions for tomorrow.

From securing the operating license to the digital automation of diverse material and goods flows: The demand for the modernization of existing intralogistics systems is increasing enormously. This is because requirements and technologies are developing rapidly. Technology is helping companies remain competitive through maximized performance and energy efficiency to keep up with Industry 4.0 trends.

With a comes to customizing retrofits, we bring your warehouse solution up to the latest state of the art technology to improve performance and system availability with greater efficiencies in maintenance and lower operating costs. This enables you remain to competitive, while future-proofing your place in the market.

From many decades as a manufacturer and provider of intelligent complete intralogistics solutions, we know the technology of yesterday - and have the technologies and expertise for tomorrow.

From modernization consulting to retrofits for complete intralogistics pallet and container warehouses.

From the replacement of mechanical and system controls or individual components and equipment groups to the elimination of accident-related machine damage and the renewal of material supply transfer systems.

From adaptations to current safety standards and norms to connection to current ERP and business intelligence systems.

We rely on wear-resistant materials, innovative energy management concepts for electric drives and intelligent control technology that optimize travel and movements, reduce dynamics and thus mechanical wear and significantly improve energy use (through storage and energy recovery modules).

Thanks to our in-house production and workshop, we can rework or reproduce components that are no longer available in a safe and functional manner. This is also particularly helpful when upgrading older systems and equipment that are no longer produced or for which spare parts are no longer available from the manufacturer.

Our production and workshop have all the necessary certifications for this.

We design exactly the right modernization solution for your storage system. And because we upgrade during ongoing operations, with only a few short interruptions, you benefit from the new operating efficiency almost from day one.

Up to 50 %

Energy cost savings

100 %

System availability

100 %

Spare parts availability