Depalletizing and palletizing for deliveries to the stores - directly from production or producer to the store mix pallet: With the Stöcklin CasePicker Solution you can easily create the premier class of intralogistics - and reliably move even sensitive goods gently and without intermediate storage 24/7/365.

Picture a scenario where you could significantly reduce unnecessary goods movements within your warehouse. Imagine your automatic direct picking system adapting its speed according to order volume. This optimization process would not only enhance efficiency but also enable you to achieve superior pick quality for up to 300 stores, faster, more efficiently, and with minimal energy consumption.

The innovative Stöcklin CasePicker Solution offers you an integrated, automated solution for food retail, stationary retail and micro-fulfillment centers (with fresh food areas of >0°C and up to 150,000 containers/day for fruit and vegetables or other food products), which allows you to pick the delivered article pallets directly onto store-optimized mixed pallets in your distribution center without operational changeovers.

Different returnable and non-returnable containers, with the basic formats 400 x 600 mm or 400 x 300 mm, are automatically depalletized, pre-stacked, sequenced and palletized directly from the article pallet in any mix, so that neither intermediate storage of the containers in shuttle warehouses nor buffers are necessary. Thanks to negative picking options, it is also energy and cost efficient!

The higher throughput, shorter throughput times on a small footprint (maximization of P/h/m²), without operational upheavals, enables sustainable process optimization and cost reduction. In addition, in contrast to conventional solutions, only a fraction of the energy is used for scalable and flexible system utilization. Ergonomic work processes throughout the entire material flow ensure a significant reduction in physical strain and greater job satisfaction among employees. Fewer employees can create a significantly higher turnover and therefore security of supply for your store network. And you can use the manpower you save in other ways. Automated picking with intelligent control enables an error rate of almost 0% to be achieved.

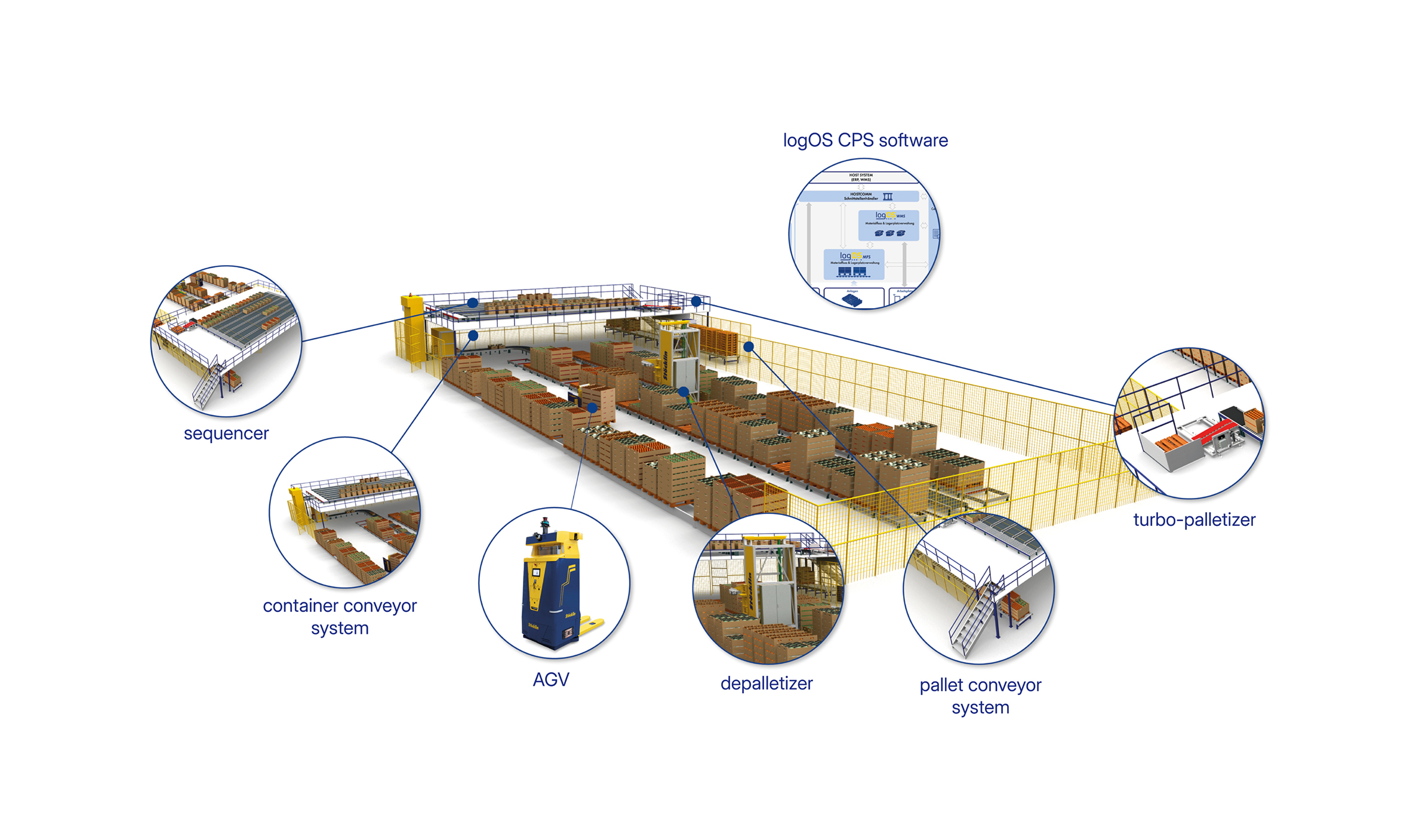

The heart of the solution is the intelligently controlled and mobile Stöcklin CasePicker Solution depalletizer robot, which is provided with replenishments by automated guided vehicles (AGVs). The innovative special gripper solution with combined vacuum and mechanical grippers and underride plate ensures particularly gentle and safe removal and gentle depositing of the non-returnable and returnable containers on the conveyor system. The packs are transported to the palletizer via our pre-stacker, lift and sequencer so that they can be fed to the Stöcklin CasePicker Solution Turbo palletizer in the optimum sequence and stacked on the store pallets provided. Thanks to the intelligently controlled stacking (heavy items at the bottom, light items at the top, structured according to the product range), a stable mixed pallet is created, packed according to the store requirements, without damage to the containers or the goods. Our specific logOS CasePicker Solution process optimization software ensures that the right pallet is in the right place at the right time.

With pick & place robot solutions from Stöcklin, your packs are safe on the move.

Pick & place robots

Intelligent automation is the future of intralogistics. Increase your capacities with our gantry robot solutions.

Portal robot