Our flexible modular system for automated storage systems offers you powerful solutions for single or multiple-deep storage of pallets and containers and small parts containers.

We design future-proof and scalable automated multichannel storage system solutions that are precisely sustainably tailored to your specific industry, product and company requirements and can grow with your needs. Whether single or multi-deep storage: our modular concepts give you maximum flexibility and high storage density as well as 24/7 fast access, high throughput and optimally coordinated material and data flows.

With more than 90 years of intralogistics experience and over 1,000 successfully installed automation solutions worldwide, we now offer you a tried-and-tested, demand-oriented modular storage system that can be scaled as required.

In the automated small parts warehouse, our FSP Shuttle transports a wide range of container types and dimensions and our BOXer storage and retrieval machines move small parts in standard containers and trays as well as a wide variety of cartons for single or multi-user storage.

In automated pallet warehouses, our modular stacker crane portfolio with the MASTer models 2024, 2032 and 2042 ensures the smooth storage of pallets at single or multiple depths in a high-bay system.

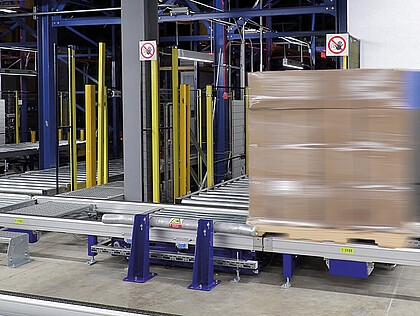

For all areas of the warehouse, we also supply flexible and cost-conscious special solutions for different storage environments, such as refrigerated and deep-freeze warehouses, or explosive environments. Our automated conveyor technology for pallets and containers, precise order picking systems and our own Stöcklin shelving systems complete the modular system. And with our logOS software suite, which has been perfected for the orchestration of our system solutions, you have all the threads for high-performance control of your automated warehouse technology in your hands. This provides you with a powerful overall system solution, precisely tailored to your specific requirements.

At Stöcklin, our team assembles and tests the systems solutions at our Technology Center in Laufen, Switzerland. The high standards of Swiss manufacturing is showcased in our quality solutions, and combined with our Life-Long Services, our team ensures superior availability and high retention with impressively low total cost of ownership (TCO).

Analysis & consulting

There are no standard solutions in intralogistics. Every company and every situation is unique. As part of a comprehensive consultation, we work with you to develop the optimal logistics solution for you and implement it successfully - based on our experience and digital analyses.

Conception & realization

You have well-founded plans and now you need an experienced partner for detailing and implementation? We accompany you from the first step of conception and project planning to the delivery of complete turnkey systems.

Maintenance and servicing

Your success stands and falls with trouble-free intralogistics. That's why we offer everything you need for maximum operational readiness of your storage and conveyor technology. In particular, strong customer service and the right service agreements for you.

Spare parts

Stöcklin offers a long-term original spare parts guarantee for its own products - and a high availability of spare parts for products from other manufacturers. No matter where your system is located.

Service Desk

Rapid troubleshooting is essential for resilient operations. It creates security for your delivery readiness and your customers. That's why the Stöcklin Service Desk is ready for you 24 hours a day, 365 days a year

Bell Food Group AG, Basel, CH

A real alternative to the previously laborious manual order picking...

To Case Study

Cooperative Storage Library Switzerland, Büron, CH

An intelligent hub for the highly automated archiving and digitally managed handling of library collections.

To Case Study

BRACK.CH, Willisau, CH

Doubling of logistics capacities with greater reliability and faster delivery speed.

To Case Study

EMS-CHEMIE, Domat/Ems, CH

Latest solution for fully automated handling of industrial pallets up to 45 m high for EMS-Chemie AG.

To Case Study

Fresenius Kabi, Wilson, US

New automation solution for Fresenius Kabi in Wilson (USA) to meet growing delivery requirements and safety regulations.

To Case Study

OMEGA AG, Biel, CH

A turnkey creation of integrated production logistics with a zero-defect strategy for the Swiss watch manufacturer OMEGA S.A.

To Case Study