Convenient, fast and reliable picking, counting, merging, storage and retrieval in the automated small parts warehouse. Our intuitively operated high-speed picking station is just right for your challenge.

In increasingly dynamic and demanding logistics environments, do you need to make your picking processes more efficient and error-free? The Stöcklin SpeedCom is our answer: The high-performance picking workstation enables a convenient, fast and reliable picking process.

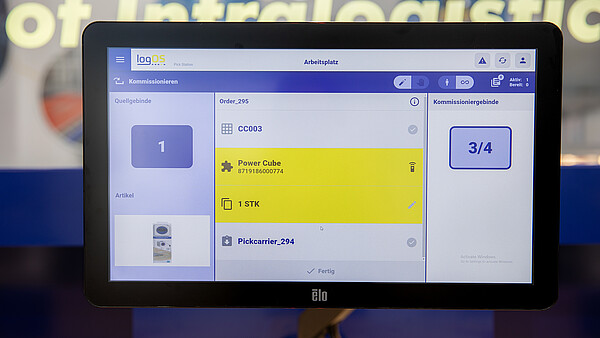

The SpeedCom is equipped with two chutes for supplying source and target containers as well as a central touchscreen and scanner and can support picking with pick-by-light technology. This provides efficient support for standard manual processes such as the storage and retrieval of small parts, the compaction of containers that are not optimally filled, stock counting, preparation for production and, above all, the picking of shipments for outgoing goods.

Source containers are reliably provided by the conveyor system in less than three seconds. Articles and removal quantities are clearly visualized on the screen. Light points indicate the correct compartment for subdivided packs. Article movements are recorded with a built-in or hand-held scanner and completed via touchscreen and/or acknowledgement button.

The source and target locations can be rotated or swapped via the control software if required. Working height, monitor position and lighting conditions are adjustable and can be adapted by the order picker to suit individual circumstances: all in all, maximum convenience for your employees.

Containers are fed to and removed from the SpeedCom at the same time as the manual picking process. With provision times of less than three seconds, container changes of less than two seconds and average picking speeds of the order pickers, a throughput of up to 900 containers per hour is possible.

The entire picking process is controlled via the Stöcklin logOS WMS, Stoecklin's warehouse and order management system.