Offering maximum flexibility for container types and dimensions, strong 24/7 performance regardless of the building, the flexible Stöcklin FSP Shuttle allows you to move more in your small parts warehouse.

Our FSP Shuttle system solution offers users an automated transport system for small parts warehouses that can scale and grow to operations. It is designed for performance and maximum flexibility, allowing you to meet increasing order volumes, shorter delivery times and other growing requirements with ease. The scalable overall package of racking system, lifters, rack conveyors, shuttle vehicles and control software can be tailored precisely to your specific system performance.

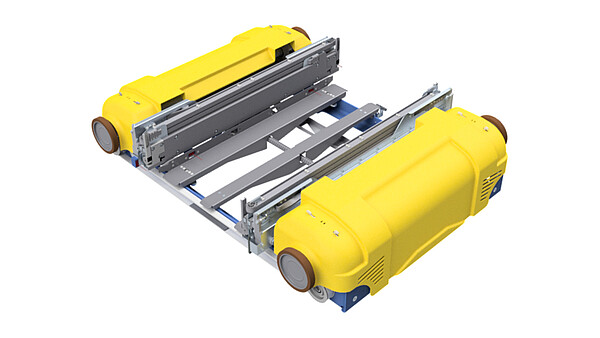

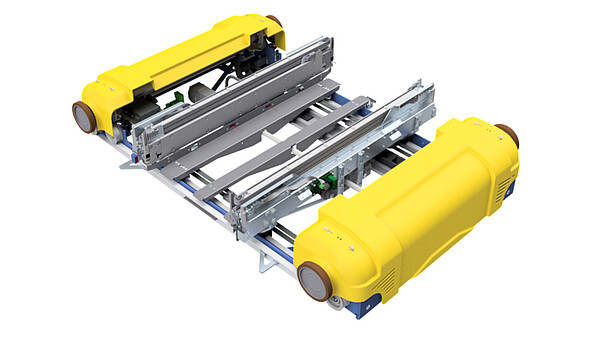

Dynamic FSP shuttle vehicles form the heart of our solution. These take care of storage and retrieval on the individual storage levels. The transported goods are picked up by a variable load handling device, which is adjustable in width. This means that the parts can be stored in the rack one or more levels deep and transferred precisely to the FSP shuttle vehicles. The vehicles are carefully coordinated with each other and have container-specific driving dynamics. This means that your small parts are always transported safely and at maximum speed. Thanks to the modularity and compatibility of our miniload FSP Shuttle system solution, it can be easily and efficiently integrated into your existing buildings.

Redundancy, interchangeability and fast accessibility of our FSP shuttles ensure maximum availability, which is further increased thanks to tried-and-tested components and a coordinated control concept. Our integrable logOS WMS software reliably controls the orders, which are processed reliably by the aisle controller of our FSP system.

Our FSP shuttle solution is designed for handling containers, cartons and trays weighing up to 50 kg. We store 400 x 600 mm containers or 440 x 640 mm trays double-deep as standard.

Our solution also offers maximum variability:

Adjustable telescopic gripper: an adjustable telescopic gripper enables the storage of packs in various dimensions (min. 200 x 200 x 50 mm, max. 860 x 660 x 500 mm).

Multi-deep storage: both standard packs and packs in special sizes can be stored multiple deep (MWS = multi width shuttle).

Parallel operation: The shuttle vehicles carry out their work in parallel and independently of each other throughout the entire system.

Interchangeability: The shuttle vehicles can be easily replaced during operation without downtime if required.

This means you can be sure that your products are stored efficiently and safely.

Analysis & consulting

There are no standard solutions in intralogistics. Every company and every situation is unique. As part of a comprehensive consultation, we work with you to develop the optimal logistics solution for you and implement it successfully - based on our experience and digital analyses.

Conception & realization

Do you have well-founded plans and now you need an experienced partner for detailing and implementation? We accompany you from the first step of conception and project planning to the delivery of complete turnkey systems.

Maintenance and servicing

Your success stands and falls with trouble-free intralogistics. That's why we offer everything you need for maximum operational readiness of your storage and conveyor technology. In particular, strong customer service and the right service agreements for you.

Spare parts

Stöcklin offers a long-term original spare parts guarantee for its own products - and a high availability of spare parts for products from other manufacturers. No matter where your system is located.

Service Desk

Rapid troubleshooting is essential for resilient operations. It creates security for your delivery readiness and your customers. That's why the Stöcklin Service Desk is ready for you 24 hours a day, 365 days a year